|

|

|

|

|

Ni-Ti

alloys with pseudo-elasticity /

shape-memory for medical applications

|

|

|

|

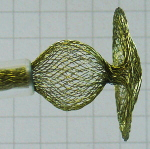

Ni-Ti

alloys are a class of alloys that feature some very special (and in

their combination absolutely unique) properties, particularly shape

memory, pseudo-elasticity and biocompatibility. For several decades,

their usage in technical applications has been rather limited though,

until their applicability for medical implants was discovered and more

and more exploited. Minimal invasive surgery techniques have been

completely redesigned and drastically enhanced by using shape memory or

pseudo-elasticity and an adequate construction. Implants made of Ni-Ti

can be folded and positioned at their location in the human body

through a catheter. Upon leaving the catheter they unfold, resume their

original shape and fulfill their function, e.g. support blood vessels

(stents) or close holes in the body tissue (occlusion devices).

|

|

|

|

|

|

|

|

|

Oxidation

mechanism of Ni-Ti

|

|

|

|

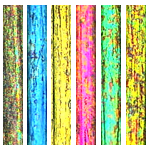

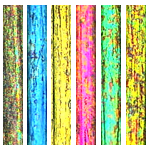

One

of the hazards of Ni-Ti alloys is the potential Ni release during its

application. In contact with human tissue the Ni release may cause

allergic reactions or inflammatory response. However, a well designed

surface layer of almost Ni-free Titanium oxide can prevent the Ni

release effectively. The oxide layer also passivates the material with

respect to corrosion. It can be generated by a tailored heat treatment

under air atmosphere, or by electrochemical processes. The type and

amount of defects in the oxide layer strongly influence its behavior.

The most crucial parameter is the oxide layer thickness. It can even be

judged (qualitatively) by the color of the material, as the oxide layer

thickness is subject to interference phenomena with visible light. To

generate almost Ni-free surface oxide layers that prevent Ni-release,

understanding the oxidation mechanism of Ni-Ti plays a key role. The

diffusion processes during oxidation are investigated in marker

experiments using different stable isotopes of the constituent elements

and resonant Rutherford Backscattering Spectroscopy (RRBS).

|

|

|

|

|

|

|

|

|

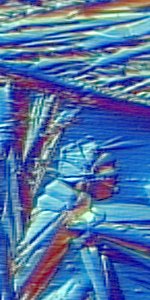

Mechanical

stability of oxide layers on Ni-Ti during pseudo-elastic deformation

|

|

|

|

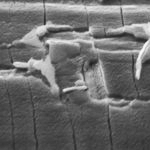

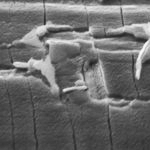

When

during oxidation an essentially Ni-free surface oxide layer is formed,

mass conservation requires that underneath there is a layer that is

enriched in Ni. The mechanical stability of the oxide layer upon

pseudo-elastic deformation is critical inasmuch as damage to the oxide

layer will set the Ni-rich layer free, and the effective protection

against Ni-release from the alloys will deteriorate. The formation of

macroscopic defects is investigated by in-situ straining experiments in

the SEM. Depending on the thickness of the surface oxide layers

different kinds of disruptions are observed. If the thickness of the

oxide layer exceeds values of 80nm, the overlay of longitudinal

deformation and transversal contraction will result in partial flaking

of the oxide layer. Thus controlling the thickness is a fundamental

aspect concerning the mechanical stability of the oxide layers.

|

|

|

|

|

|

|

|

|

Structural

properties of Ni-Ti for medical application

|

|

|

|

To

achieve the best possible results in surgery with NiTi Implants,

reproducible adjustment of the structural properties such as strength

or pseudo-elastic deformation, is necessary.

Pseudo-elasticity and shape memory effect are governed by the

martensite-austenite transformation of the NiTi phase. In the present

project the options of controlling the transformation temperature and

the transformation characteristics by short time annealing are

investigated. Depending on duration and temperature of the annealing,

substantial alteration of transformation temperatures and

transformation characteristics occur. Detailed investigations are

carried out to characterize the complex interactions of recovery,

recrystallization and the formation of Ni-rich precipitates. One of the

basic results is that the material’s properties are extremely

sensitive to slight changes in the annealing parameters – for

medical purposes a precise control of the annealing parameters is

indispensable.

|

|

|

|

|

|

|

|

|

Characterization

of the fatigue behavior of occlusion implants

|

|

|

|

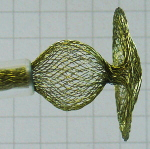

A

fatigue testing device has been developed that mimics loading and

deformation of occlusion implants in the human body. The conditions

during the application like deformation lengths, type of deformation,

surrounding liquid medium and temperature are generated in a mechanical

testing device. The fixation of the occlusion device in the machine is

the key problem: the self-attachment of the occlusion device in the

human heart cannot be imitated in a way that at the same time a similar

deformation mode is generated. Special fixations have been designed for

different deformation modes. The implants are exposed to a series of

107 deformation cycles with a frequency of ca. 4Hz, for documenting the

fatigue strength of the occlusion device. For a good visibility most of

the parts of the mechanical testing device are made of PMMA (plexi

glass). 16 implants can be tested at the same time. Until present

several tests were carried out successfully, proving the fatigue

resistance of the investigated occlusion implants that is necessary to

obtain governmental approval.

|

|

|

|

|

|

|

|

|

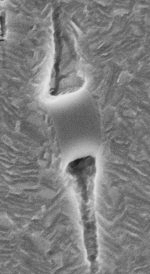

Non-martensitic

needle-like structures on Ni-Ti alloys

|

|

|

|

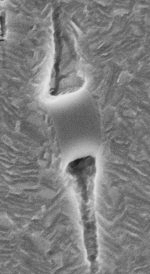

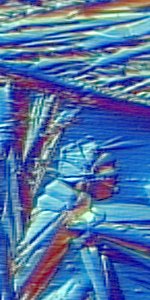

Metallographic

preparation for microstructural studies on Ni-Ti alloys is by no means

trivial. The literature mentions several possible routines, but also

potential pitfalls: several phenomena like stress induced martensite or

ghost martensite can complicate concise interpretation of the

microstructure. In addition to these known phenomena, the occurrence of

needle-like structures is frequently observed on martensitic and

austenitic NiTi after metallographic preparation and etching. These

needle-like structures look very similar to martensitic structures.

Hence it is tempting to interpret them as martensite. Distinguishing

the structures from martensite is not straightforward, since EDX does

not yield any differences in chemical composition of the needle-like

structures and NiTi. Application of surface sensitive methods like

grazing incidence X-ray diffraction, glow discharge optical emission

spectrometry (GDOS), XPS and AES clearly show that the needle-like

structures are different from martensitic structures of NiTi and that

the material’s surface plays an important role to understand

the

formation of the structures.

|

|

|

|